Grinding Media | Glen Mills

Grinding Media is used to finely grind ore material to a size which allows recovery of the desired contained material.

WhatsApp)

WhatsApp)

Grinding Media is used to finely grind ore material to a size which allows recovery of the desired contained material.

Split and easily detached, they are equipped with a special gasket held in tension by a special springloaded device, assuring a dusttight seal between mill ...

The Emax is an entirely new type of ball mill for high energy milling. The Emax combines high friction and impact to create extremely fine particles.

Allis Chalmers Svedala ball mill, 13'' diameter x 21'' long, rubberlined mill, with SiemensAllis 2,000 HP, 4000 volt, 200 RPM synchronous motor, Eaton airflex clutch.

83 Centrifugal force outward Fc mp 2 Dm 2 () is the angular velocity, mp is the mass of any particle (media or charge) in the mill and Dm is the diameter of ...

Cost economic grinding media balls for mines and minerals processing industries from AIA Engineering Ltd.

Unicast Grinding Mill Parts combined provide a complete system for optimized wear life of grinding mill parts with cost savings and minimum down times.

Keep that circle moving, and there is plenty of money to be made, as the Duluth grinding ball plant on Garfield Avenue has shown over the past 40 years.

The DMQX bead mill from Union Process provides highly effective, reliable circulation grinding, producing uniform fine dispersions with superior product quality.

We sell all types of Grinding Mills, Rod Mills, Pebble Mills, SAG Mills, Ball Mills, if you are looking for partial or complete replacement for all the ball mill ...

STR Industries is an manufacturer and supplier zirconia ceramic grinding media for mixing, crushing, dispersing and purifying variable materials.

How to optimize a 6 pound ball mill to safely and effectively ball mill homemade black powder.

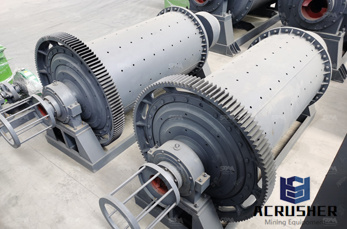

The ball mill is a key piece of equipment for grinding crushed materials, and it is widely used in production lines for powders such as cement, silicates, refractory ...

Learn about our Sepro Tyre Drive Grinding Mills, including description, applications and specifications, for your mineralprocessing needs.

Improving The Efficiency Of Fine Grinding – Developments In Ceramic Media Technology Curry D C1; Clermont B2 1Technical Superintendent Mineral Processing; .

ATTRITOR GRINDING MILLS AND NEW DEVELOPMENTS I. INTRODUCTION AND PRINCIPLES In this presentation we will discuss the principle of the Attritor and its .

The CryoMill is tailored for cryogenic grinding. With its liquid nitrogen cooling system the Cryomill keeps the temperature at 196 °C. Read more.

Unused FL wet grind overflow ball mill, 27'' ( m) diameter x 46'' ( m) long. Discharge with MW (20,500 kW) gearless wrap around motor drive, 50 Hz ...

International journal of advanced scientific and technical research Issue 4 volume 1, JanuaryFebruary 2014 Available online on ...

FOX Zirconium Silicate Grinding Media is the right ceramic grinding media for you. Why take chances with any other inferior milling media for your bead milling.

SWECO VibroEnergy Grinding Mills are the most versatile line of mills available today for fast, lowcost particle size reduction to submicron range.

Cement grinding Vertical roller mills versus ball mills Soeren Worre Joergensen MSc, General Manager, Engineering, Grinding Technology

Figure 1 : Grinding Power to produce various product sizes in a Ball Mill (9mm balls) and an Isa Mill (2 mm sand) (for KCGM pyrite concentrate)

A pulverizer or grinder is a mechanical device for the grinding of many different types of materials. For example, a pulverizer mill is used to pulverize coal for ...

WhatsApp)

WhatsApp)