AMORPHISATION PROCESS DURING .

Amorphisation process during mechanical alloying of AlFeTi powders and crystallisation of ... XRD patterns of AlFeTi powder mixture at indicated milling times.

WhatsApp)

WhatsApp)

Amorphisation process during mechanical alloying of AlFeTi powders and crystallisation of ... XRD patterns of AlFeTi powder mixture at indicated milling times.

Processing of Magnetite Iron Ores – Comparing Grinding Options ... process facility would be built on ground of a sound ... PROCESSING OF MAGNETITE IRON ORES ...

Synthesis of nanomaterials by a simple, low cost and in high yield has been a great challenge since the very early development of nanoscience. Various bottom and top ...

The unique IOSSOFE Process can be bonded directly to all iron based metals, ... The bright uniform outline of this end mill cross section shows the Iosso process.

Abstract In the present work, Fe based ODS alloy (84Fe14Cr2Y 2 O 3) was fabricated using a very high speed planetary milling process and their microstructures were ...

3D Parametric Modelling of Milling Cutter Geometry ... of Milling Cutter Geometry from Analytical Analysis. ... in FE simulation studies of milling process. ...

iron ore fe lt 58 still mill process; 10 24 30 am roger sbm china; calculate ppm of fe in iron ii ammonium sulfate hexydrate;, ...

Proceedings of Precision Engineering and Nanotechnology: 3D FEBased Modelling and Simulation of the Micro Milling Process

A new premilling coating process was developed. • Formation of FeAl, Fe 2 Al 5 and FeAl 3 were observed. • The coating structure was examined by Xray ...

cfc_, losses in earnings which were still piling up against the ... 50,000 mill hands and ... How far this process will go is still millenium.

of Fe based ODS alloys by a very high speed planetary milling Park, a planetary mechanical millingprocess is widely used at milling speeds ranging ...

Möss Study of the Ball Milling Disordering Process of FeAl Intermetallic Compounds ... Structural changes during ball milling of ordered Fe 50 Al 50 ...

Flakeshaped FeSiCr alloy powders were prepared by crushing alloy ingots and the ball milling method. Magnetic properties of FeSiCr alloy powders with the nominal ...

Corn oil is a coproduct in the wet milling process, in which ethanol, corn gluten meal and corn gluten feed are produced as well.

The paper details research and development of a Lagrangianbased, 3D finite element (FE) model to simulate the highspeed ball nose end milling of Inconel 718 nickel ...

Milling is used as one of the most important tools with the complex tool geometry in industry. However, the complex milling process cannot be simulated by 2D finite ...

Processing and Synthesis of Nanomaterials. ... Fe is evaporated into an inert gas ... However, it can be fabricated by mechanical alloying using ball milling process.

Smelting is a process of applying heat to ore to melt out a base metal. It is a form of extractive metallurgy. It is used to extract many metals from their ores ...

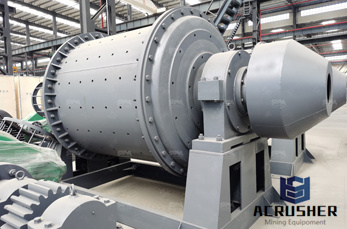

milling process of fe. fe doped batio3 solid state mechanical milling ctpa. Two steps were involved: ball milling for 2 h at 300 rpm and then a sintering at 1150°C ...

Ferrite Processing Effects on Material Performance ... process includes calcine, milling and drying. Group 3 ... In addition to Fe,O, pick up from the mill ...

Synthesis of iron doped TiO2 nanoparticles by ballmilling process: the influence of process parameters on the photocatalytic efficiency Joaquim O. Carneiro1, S ...

Studies on magnetic properties and ballmilling process ... Fe 75 Si 15 Cr 10, Fe 80 Si 10 Cr 10 ... flakeshaped powders and milling time of Fe Si 17 Cr ...

Cutting process, Milling, CowperSymonds function . 8th European LSDYNA Users'' Conference ... milling process FE model was composed taking in account Hulle

Fe Cu ... Cu Composite Powders Produced by Ballmilling Process (I) −I. Gas Atomization and Production of Composite Powders ...

WhatsApp)

WhatsApp)